Manufacturers’ warehouses swept empty

The US Department of Commerce has released the results of an extensive investigation into the global chip shortage. According to her, the crisis will continue to accompany us. Things are looking bleak, especially for car manufacturers, because their warehouses are getting emptier.

Chip shortage: no improvement in sight

Disrupted supply chains and a massive increase in demand in the wake of the corona pandemic mean that semiconductors remain in short supply. The US Department of Commerce has now specifically asked 164 large companies for their assessment. According to the survey, basically nobody expects the situation to improve in the coming months. In addition inventories are getting smaller, which mainly car manufacturers report.

According to the data, by the end of 2021, companies only had enough semiconductor inventories for five days. For some unnamed car manufacturers the warehouses are said to be even emptier. For comparison: before the corona pandemic, the average stock was sufficient for 40 days (source: US Department of Commerce).

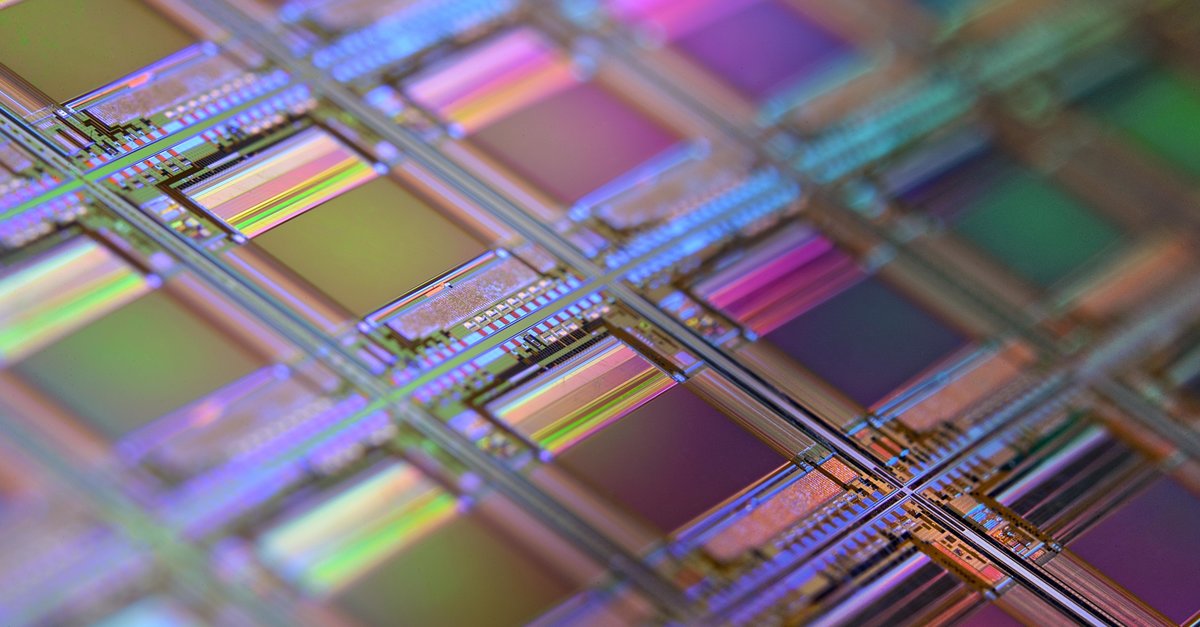

The biggest Chip manufacturers such as TSMC, Intel and Samsung continue to struggle with material shortages. According to the survey, inventories of silicon wafer blanks that are required for production are extremely scarce. In addition, suppliers cannot deliver the required quantity of chip carriers. A short-term solution to the problem is not to be expected.

How is a chip made? Intel gives the answer:

Chip shortage: With new works out of the crisis?

Some chip manufacturers are promising the second half of 2022 Commissioning of new semiconductor factories. It is said, however, that the situation will only relax in a way that is noticeable around the world in the next few years. Intel alone wants to spend more than 20 billion US dollars on new plants in the USA.

In global delivery traffic, even containers are now becoming a scarce commodity. These are currently on average only reloaded after 60 days, as many ports are overloaded.