This is how Plantd Materials wants to revolutionize house building

The US start-up Plantd Materials would like to no longer produce chipboard for houses from wood, but from grass. The goal: to make the construction industry more sustainable and eliminate pollutants.

In a way, the coming years will decide the future of our planet. Will the earth become an uncomfortable place where heat and storms dominate? Or do we mitigate the impact of our emissions and build an even better and more sustainable planet? We have it in our own hands.

In 2020 came about still almost 40 percent our emissions from the construction sector. One reason is the production of cement, which requires high temperatures. This usually requires environmentally harmful furnaces that emit large amounts of greenhouse gases. The company Plantd Materials therefore wants to revolutionize house building: with houses made of grass.

Plantd Materials wants to build houses out of grass

The key lies in the use of coarse chipboard. Because even today, many builders use an alternative material that guarantees stability with a low environmental balance. Previous models, on the other hand, rely on long shavings of wood, which the manufacturers glue together under great pressure. To do this, they use industrial waste.

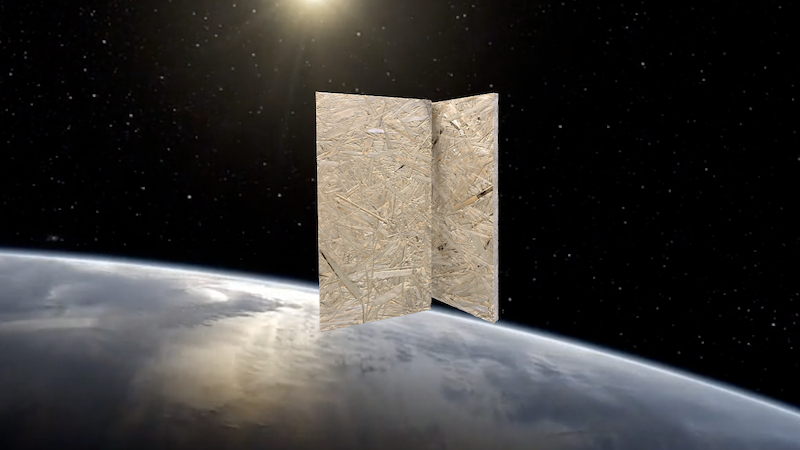

Not so with Plantd Materials. Because the company produces panels measuring 1.2 × 2.4 meters and only uses grass for this. About 23 kilograms of the material are stuck in a plate, which probably consists mainly of bamboo and reed. The start-up has not yet given any specific information.

Many advantages compared to classic coarse chipboard

However, the panels are said to be more stable than their wooden counterparts and at the same time repel more moisture while being lighter. The use of grass meanwhile requires significantly less land than when using wood. For a medium-sized factory, the company needs about 57,000 hectares of forest land.

Since grass also grows much faster than trees, Plantd Materials can harvest the necessary raw material every year. For classic wood farms, it is about ten to twelve years. So all in all, the company’s sheets could one day significantly reduce emissions from the construction sector.

Also interesting: